Email: enquiry@cksmachining.com Tel: (+86) 18022058253

5-axis machining is an advanced CNC machining technology, through the CNC system control in multiple directions (X, Y and Z, as well as A and B) movement and rotation for cutting, compared with the common 3-axis or 4-axis machining, 5-axis machining for highly complex parts processing is more convenient, more flexible and more diversified, to save the machining process and time, positioning accuracy, to avoid errors due to multiple clamping of manually positioning the workpiece.

5-axis machining is highly technical, so we have specialized 5-axis engineers on staff.When machining difficult and complex parts, engineers precisely control the machine to move cutting on multiple surfaces through the CNC system, which can operate multiple surfaces machining at one time.5-axis machining offers advantages over conventional equipment in terms of machining accuracy, machining efficiency and consistency, and with our company you get very competitive pricing and quality.

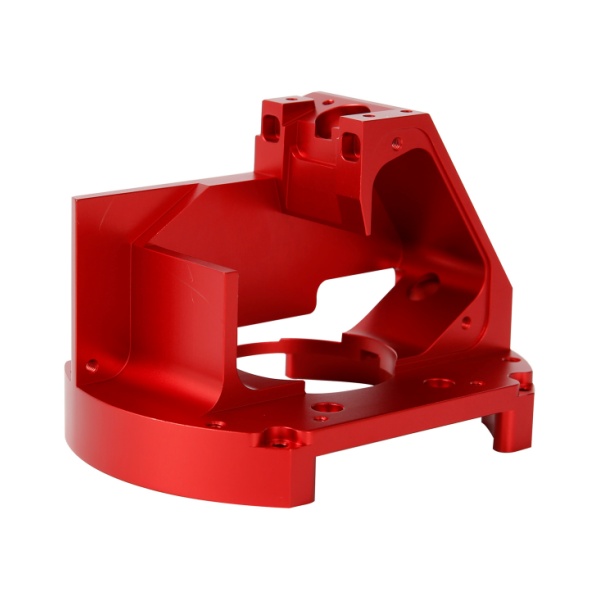

Machining Complex Shapes

Whereas in conventional machining we usually have to machine complex parts with multiple special fixtures to position them for machining, the 5-axis milling process allows you to rotate the part in a single operation to machine 5 surfaces at the same time in order to achieve the desired complex shape without multiple fixtures.

If we need to process complex parts, the programming and operation involved is much more difficult, so we need to deploy higher level engineers to operate the machines, which will mean an increase in labor costs.

5-axis CNC machining is used in a wide range of industries and has brought about historic reforms to the industry,Let's take a look at common processing applications:

5-axis machining in the automotive industry

Some automotive components such as engine cylinder heads, steering shafts and automotive lights require high precision and complex machining processes. 5-axis machining not only responds to the ever-changing design needs of the automotive industry, but also provides automakers with greater flexibility and room for innovation.

|

Quote Now to Start Your 5-axis parts Project

If you need to machine complex parts with high quality surface finish, please try to send files to us, we will provide you with excellent service and price.

|