Email: enquiry@cksmachining.com Tel: (+86) 18022058253

What is Rapid Tooling?

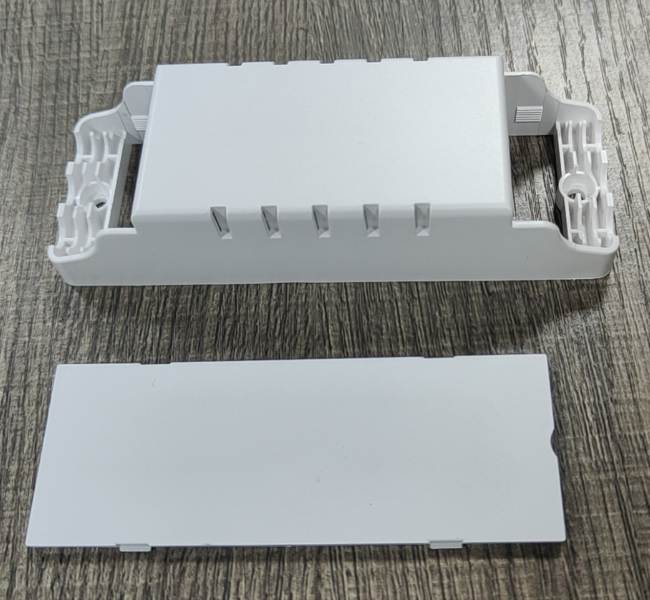

Rapid tooling is a relatively new method in mold manufacturing, known for its short production cycle and competitive pricing. The advantages of rapid tooling help accelerate the time-to-market for product designs and are also suitable for mass production. The plastic parts produced through rapid tooling are widely used in industries such as automotive, electronics, and medical, providing efficient and flexible solutions for production.

Our Rapid Tooling Process

Requirement Analysis: We have extensive experience in helping customers with professional rapid prototyping services and prototyping services, deeply understanding the performance and use of their parts to ensure that the customized molds meet the highest quality standards.

Design Phase: Our team of professional engineers quickly designs mold structures that meet customer requirements, conducting simulations and optimizations as needed.

Material Selection: Based on the characteristics and quantity of the parts, we select suitable mold steel to ensure the molds produce high-quality parts and have a long service life during subsequent processing.

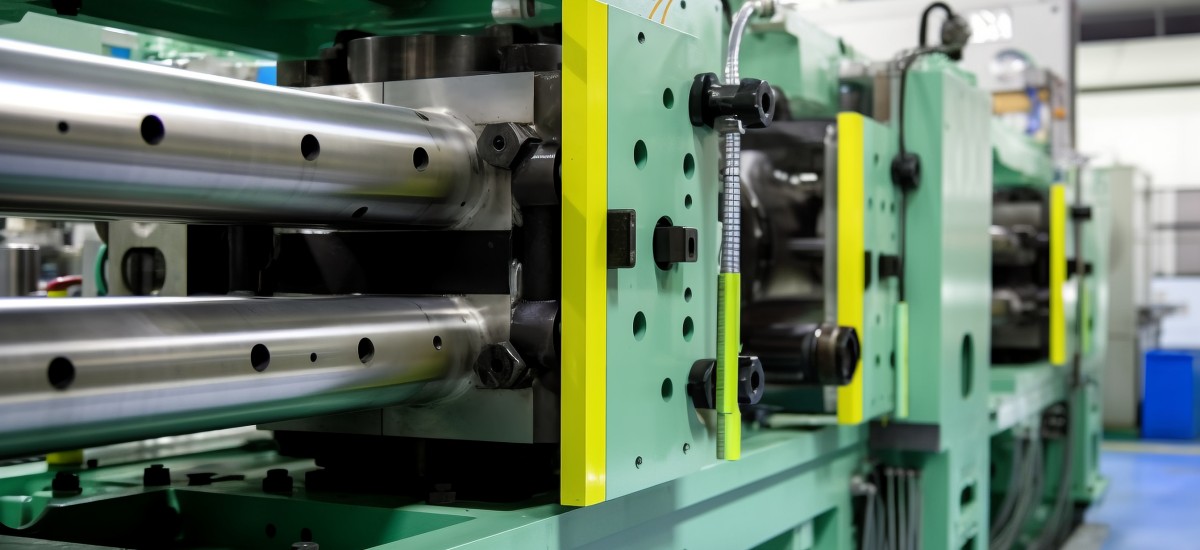

Rapid Manufacturing: Our company has an in-house mold department responsible for achieving rapid manufacturing of molds, significantly shortening the delivery cycle through our rapid prototyping services.

Testing and Adjustment: Before part production, the molds undergo rigorous testing and adjustment to ensure that the processed parts meet the standards.

Efficient Production: The manufacturing speed of rapid tooling is fast. For simple parts, production can start in as little as one week, helping customers bring products to market quickly.

Cost Advantage: Rapid tooling offers cost benefits compared to traditional molds. It meets customer needs for both small and large batch production.

Flexibility: Rapid tooling is highly reusable and flexible, making it convenient for product testing and adjustments.

Precision: Despite its short cycle, rapid tooling ensures high precision and stability of the molds, producing parts that meet quality standards.

KISUNG's small batch injection molding technology is well-developed, combining traditional injection molding with professional rapid prototyping services. We provide fast and economical custom part solutions, tailoring the best production plans based on customer needs. By considering mold life and cost investment, we create greater economic benefits for our customers.

Choosing KISUNG for small batch injection molding takes full advantage of traditional injection molding and rapid prototyping specialist techniques, offering efficient, high-quality, and personalized services.

|

Request a Quote for Rapid Prototyping Services

Our Rapid Prototyping workshop can provide one-stop service for your product pre-testing, product processing testing and product batch production.

|