Email: enquiry@cksmachining.com Tel: (+86) 18022058253

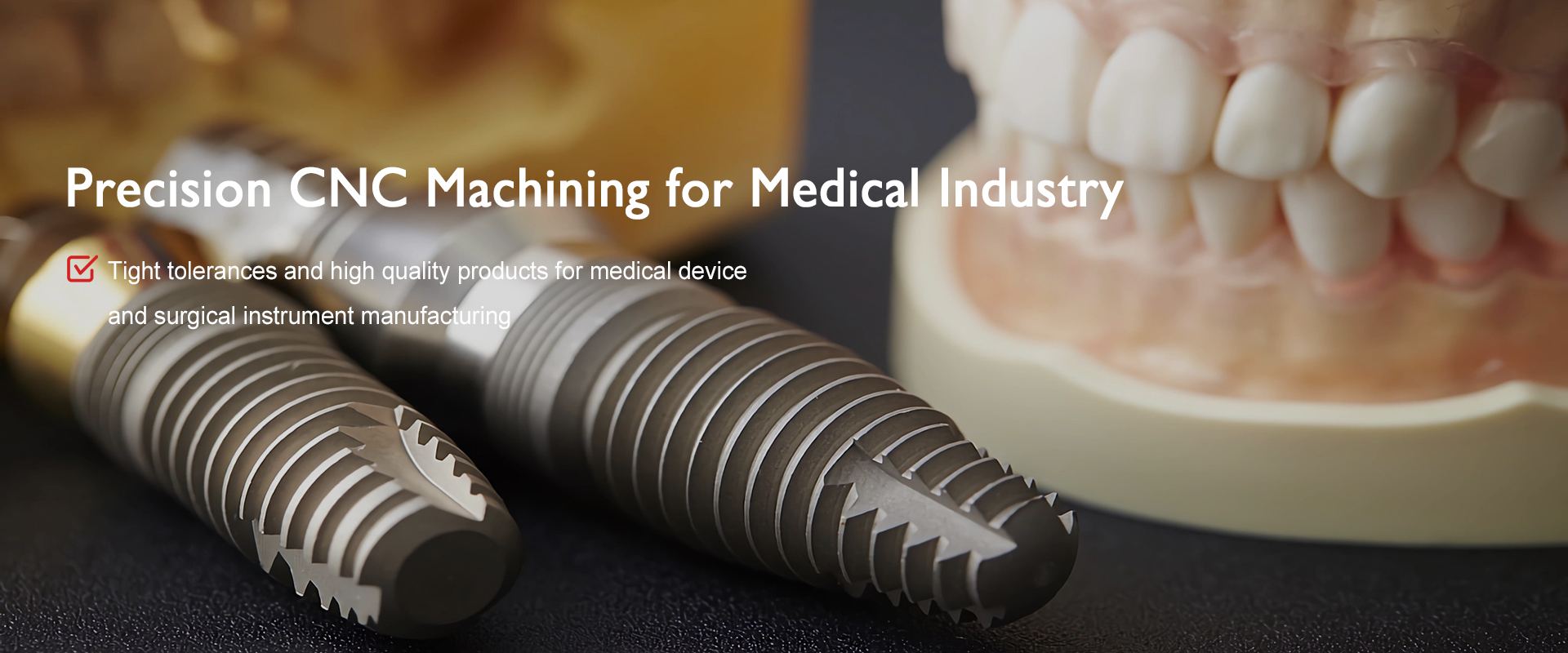

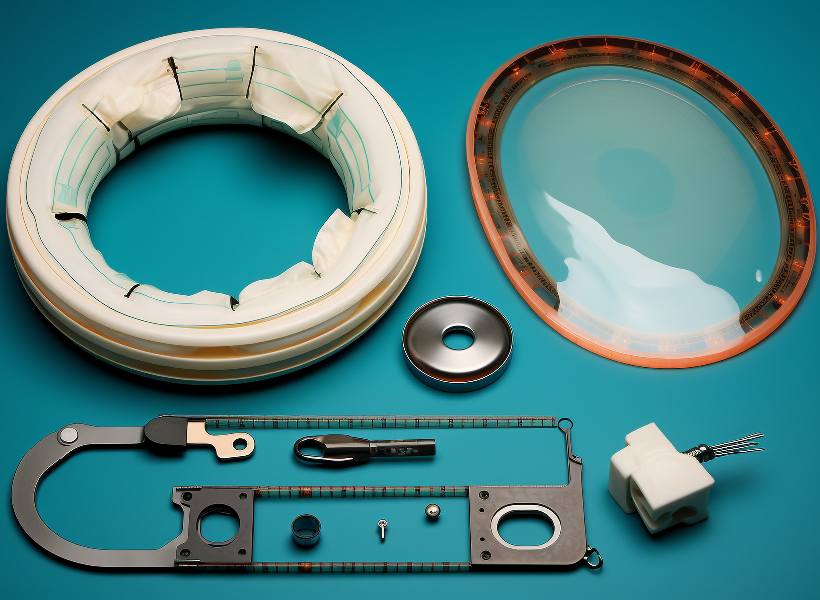

KINGSUN Customized Precision Parts supports the customization and processing of non-standard parts in multiple varieties and small batches for a variety of medical devices and equipment, such as surgical equipment, imaging equipment, endoscopes, medical robots, dental equipment and so on.

We have been supplying precision medical parts to many famous international medical companies for a long time. In order to ensure the safety and reliability of the parts, we all test 100% incoming materials and make sure every part is 100% qualified.

Why choose KINGSUN for customized medical parts?

As a technical expert in customized processing of medical device parts and components, we focus on precision, quality and reliability for each part.

One-stop service: At KINGSUN, you can get one-stop service, which is convenient and efficient.

Quality Control: Through our complete quality management system, we ensure that the parts are 100% qualified.

Cost-effective: our company's professional medical parts customization service will provide you with the most competitive price.

Professional and technical team: We have an experienced engineering team for medical equipment parts.

In the healthcare industry, medical device manufacturing occupies a crucial position as human society continues to develop. As a leader in parts manufacturing services, Kingsun continues to innovate its technology and successfully applies advanced technologies, such as CNC machining and 3D printing, to medical device manufacturing, in order to provide customers with more excellent services.

The core of medical device manufacturing lies in precision manufacturing, and we carry the spirit of craftsmanship through our pursuit of detail. Through the use of advanced CNC machining and other technologies, which are perfectly embodied in our medical device manufacturing, we ensure that each part meets the highest standards set forth in the engineering drawings.

Kingsun's Finishing Services

Our company has a precision CNC workshop, a 3D printing workshop, a sheet metal fabrication workshop and a mold manufacturing workshop. Precision medical device parts are almost always available here at Kingsun.Medical Device Parts Customization Discussion:

3D printing: an engine for medical

innovation

3D printing technology, as a new digital additive manufacturing process, has the advantages of precision, customization, flexibility and speed. Especially in the field of orthopedic and rehabilitation aids, we have overcome the roughness shortcomings of 3D printing through finishing surface treatment, which provides strong support for medical innovation.

|

Quote Now to Start Your CNC Machining Project

Do you have a suitable project here that you would like us to help with? KINGSUN will provide you with CNC milling and turning solutions and quickly manufacture the parts you need!

|