Email: enquiry@cksmachining.com Tel: (+86) 18022058253

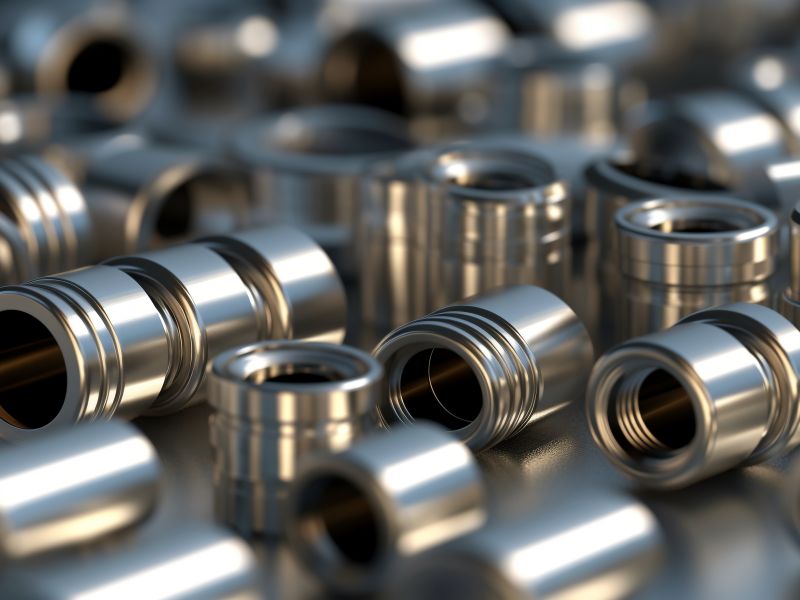

Best Manufacturer of Precision Turned Parts

Kingsun CNC turning service can realize the ideas you have in mind into the best parts, our factory has advanced CNC lathe and mill-turning compound, we can make almost all the products you need, we serve every customer with heart and soul, help customers to shorten the development time, solve the problems and save the cost as much as possible for our customers.

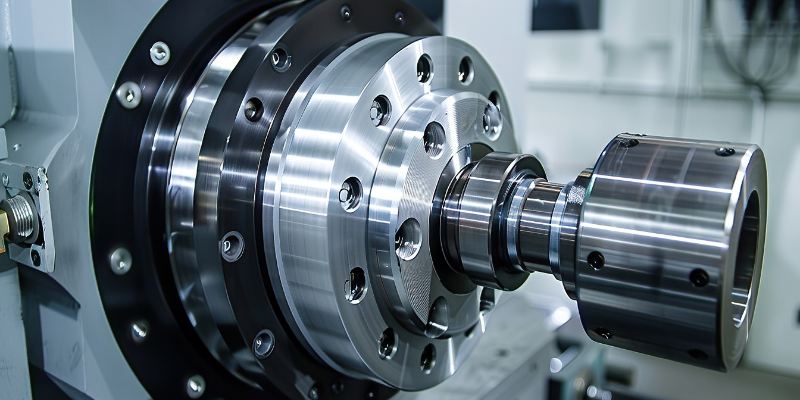

What is CNC turning?

CNC turning is the removal of material from a rotating workpiece by means of a CNC turning tool and obtaining the desired shape, it is very similar to CNC milling. More than CNC milling, the processing results in a smoother surface, a clearer knife pattern, and faster cutting speed. CNC turning for complex geometries such as cylinders, cones, and threads is performed with higher precision and efficiency. Therefore, the selection of the process should be taken into account when the parts need to choose the most suitable processing method.

CNC turning is perfect for machining axisymmetric cylindrical parts, and even features such as side holes, milled flat surfaces, and out-of-specification shapes. CNC lathes can machine metals, plastics, ceramics, and other materials. Often when machining parts engineers will consider the machining process and choose different tooling for lathe to improve the appearance of the part and shorten the overall production time, and we are willing to turn your ideas into playful reality for you.

CNC turning technology is widely used in various fields, especially in the automotive, aerospace, medical and robotics industries, for its high precision and efficiency.

Aerospace Industry:

Automobile manufacturing:

Robot Manufacturing:

With the rapid development of robotics, the precision and consistency of CNC-turned parts is critical to ensure the stability of the robot's motion and control system. CNC turning is not only capable of machining complex parts, but also improves productivity and provides critical support for robot manufacturing.

•Advanced CNC machine

Our company has a precision CNC workshop, in order to meet the different needs of customers, our company has CNC turning, CNC milling and turning and milling machining capabilities, which can efficiently produce high-precision parts and shorten the development cycle of customers.

•Experienced technical team

Our experienced engineering and quality teams will develop the most reasonable machining program after receiving your files to ensure that the parts you receive are exquisite and perfect.

• Complete surface treatment services

We are also very comprehensive in this aspect of the surface treatment services, common surface treatment of anodizing, hard anodizing, powder coating, plating, heat treatment, powder spraying, etc., and can even provide secondary processing, such as EDM, Wire cutting, laser marking, drawing, grinding, welding and so on.

• The best supplier for customers

|

Let's see what our customers say about us?

Famous European automotive parts companies have this to say about our automotive pulleys and high-speed pulleys: “The pulleys you produce are the best quality among all his suppliers.”

|

Turning processing has many processing methods, the more common are end face turning, OD processing, ID processing, thread cutting processing, cut off processing, etc. The processing methods are as follows:

Face turning and OD turning: Face turning and profile turning operations involve machining the face and profile of the workpiece, using tools that are usually external cutters that can simultaneously achieve smooth planes, curved surfaces, tapers, steps, and precise external rounds.

|

Quote Now to Start Your CNC Turning Project

Through our strong CNC turning capabilities, we can provide you with the best quality and service with fast delivery and cost control.

|