Email: enquiry@cksmachining.com Tel: (+86) 18022058253

The Importance of CNC Machining in the Automotive Modification Industry

The automotive modification industry has a long history and is known for its passion and innovation. From aesthetic upgrades to performance enhancements, both enthusiasts and professional modification companies are constantly striving for higher precision and quality. Kingsun Precision has been providing top-quality products to renowned automotive modification companies for many years. With the continuous advancement of technology and the accumulation of experience in machine shop CNC operations, CNC machining has become a critical player in this field. This article will delve into the essential role CNC machining plays in automotive modification, exploring its technological advantages and practical applications.

Contents

1.The Basics of CNC Precise Machining

2.Demands and Challenges in the Automotive Modification Industry

3.Applications of CNC Machining in Automotive Modification

4.Technical Advantages of CNC Machining

5.Case Studies

6.Future Trends in CNC Machining

7.Conclusion

The Basics of CNC Precise Machining

Introduction to CNC Machining: CNC machines are controlled by a numerical control system. Engineers use programming

software (like Mastercam, Powermill) combined with material properties, processing requirements, and machine characteristics

to create programs. The CNC system then controls all the machine’s movements and auxiliary actions based on these program instructions. Controlled actions include starting and stopping the machine, spindle direction and speed changes, feed motion direction and speed, tool selection, compensation for tool length and radius, tool changes, coolant activation, and more.

Advantages of CNC Machining: Compared to traditional methods, CNC machining offers several clear advantages, including

safety, reduced labor costs, minimal setup errors, stable precision, flexible processing, high efficiency, and broad applicability. Kingsun Precision has overcome many processing challenges and can handle various metals and non-metal materials, even

special materials, meeting the diverse demands of automotive modification parts.

Demands and Challenges in the Automotive Modification Industry

Diverse Needs of the Modification Industry: Automotive modification covers a wide range of needs, from aesthetics to performance. Enthusiasts want their vehicles to stand out visually while also outperforming standard configurations. This

drives the demand for custom parts with high requirements.

Limitations of Traditional Processing Methods: Traditional processing methods often struggle to meet the demands for

complex structural parts, particularly when high precision and small-batch customization are required. These methods

are inefficient and costly under such conditions.

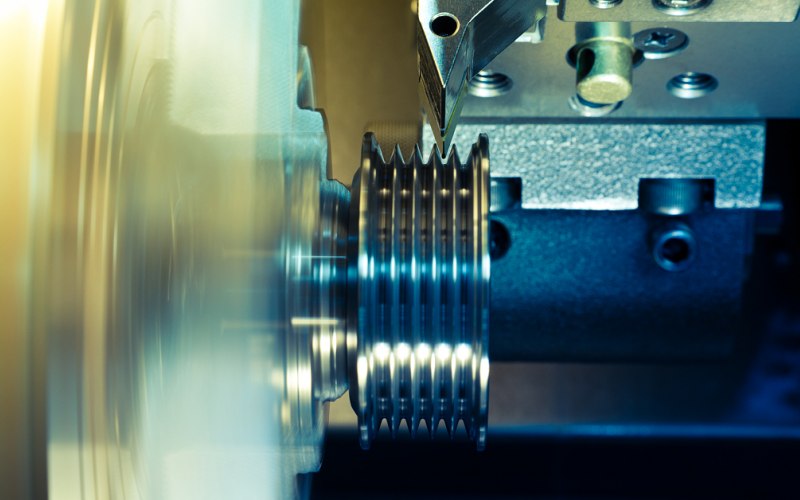

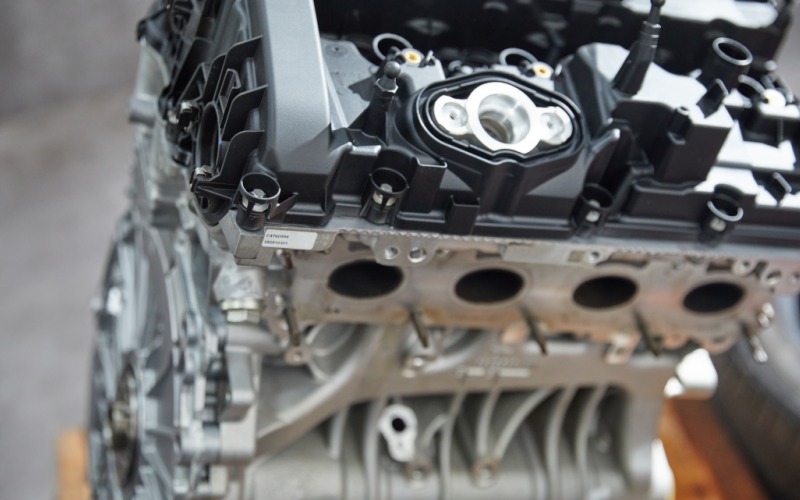

Engine Component Machining: CNC machining plays a crucial role in custom engine parts. For example, custom

Supercharger and Vortech pulleys require extremely high precision to ensure stable performance under heavy loads.

Body Part Machining: For parts involved in body modifications, such as frame reinforcements and chassis braces,

CNC machining ensures durability and precise fitment.

Suspension System Part Machining: CNC machining can produce precise suspension components, where accuracy

directly impacts vehicle handling and safety.

Other Critical Modification Parts: This includes brake system upgrades, custom exhaust systems, and intake system

modifications, where CNC machining offers high-precision custom solutions.

Technical Advantages of CNC Machining

Precision and Repeatability: CNC machining can achieve micron-level precision, which is essential for high-performance modification parts. Additionally, its repeatability ensures consistent quality across production batches.

Capability to Process Complex Structures: CNC technology can process intricate 3D structures, giving designers more

freedom for innovative designs, free from the limitations of traditional methods.

Material Versatility: CNC machining can handle a wide variety of materials, from common aluminum alloys and stainless

steel to carbon fiber composites, meeting the material requirements for different modification parts.

Production Flexibility: With high levels of automation, CNC machining allows for quick design modifications or production

task changes, offering great flexibility for custom production.

High-Performance Sports Car Modification: A sports car owner wanted to boost the vehicle's power output. With CNC

machining, custom turbocharger systems and exhaust systems significantly increased the car's horsepower, achieving

excellent track performance.

Off-Road Vehicle Suspension System Modification: CNC-machined custom suspension components enhanced an off-road

vehicle's ground clearance and stability, improving its performance in extreme conditions.

Classic Car Modernization: Some classic car modification projects have used CNC machining to maintain the original exterior

while modernizing internal structures and performance.

Future Trends in CNC Machining

CNC machining plays a vital role in the automotive modification industry. Its high precision, efficiency, and flexibility provide

strong support for enthusiasts and professionals alike. As technology advances, CNC machining will play an even more

significant role in future automotive modifications. Choosing a professional CNC machining service like Kingsun will be

crucial to ensuring the success of your modification project.