Email: enquiry@cksmachining.com Tel: (+86) 18022058253

Comprehensive guide for in-depth analysis of tap tools and techniques

In the realm of production and everyday life, thread processing is an indispensable part of machining. It creates various types of internal threaded hole in metal and other materials, allowing bolts, nuts, and other components to be securely connected. This process is widely used in industries such as automotive and aviation manufacturing. But how can we correctly process threaded hole in metal? Understanding the different threading techniques and choosing the right thread is crucial.

This article will thoroughly explore the types of tap tools, their applications, selection tips, process optimization,

and related examples to help you understand how to choose and use taps for optimal machining and assembly

esults.

Contents

What is a Threaded Hole?

Importance of Creating Tapped Holes

How Do We Create Threaded Holes?

Differences and Applications of Blind Holes and Through Holes

Detailed Explanation of the Four Main Types of Taps

Differences Between Hand Taps and Machine Taps

Important Considerations and Recommendations for Tapping Holes

Common Issues and Solutions When Using Taps for Thread Processing

cutting tool. It is a round hole commonly used to connect two parts with bolts or screws. Before processing a

threaded hole, we need to drill a corresponding pilot hole in the material. Then, the tap cuts the threads into

this hole so the bolt or screw can be smoothly inserted and secured.

Importance of Creating Tapped Holes

Thread processing is critical in various manufacturing industries, providing a stable connection point that allows

parts to be securely joined. It also allows for easy disassembly when needed, reducing transportation costs by

allowing parts to be reassembled upon arrival. In the CNC machining, accurately positioned threaded holes in metal

or other materials enable easy installation and removal of parts, making it a widely used technique in our machining

applications.

How Do We Create Threaded Holes?

Before processing a threaded hole, it's essential to select the right drill bit and tap cutting tool. The diameter and

depth of the hole significantly impact the final threading outcome, so choosing the drilling tool carefully is crucial.

Generally, a pilot drill bit is used for the initial hole, while a tap drill bit is specifically used for cutting the threads.

For different diameters and materials of workpieces, selecting the appropriate drill bit size and type is necessary to

ensure the quality of the tapped hole. Thread gauges are often used to check if the threaded hole meets the required

standards.

Differences and Applications of Blind Holes and Through Holes

When defining tapped holes, two types are typically mentioned: blind holes and through holes.

•Blind Holes: These have an opening on one side of the workpiece, with a certain depth. They are commonly

used where a part needs to be fixed or connected without passing through the workpiece entirely.

•Through Holes: These go entirely through the workpiece, suitable for scenarios where bolts or nuts need to

secure parts from both sides of the workpiece.

Detailed Explanation of the Four Main Types of Taps

Based on different needs and machining scenarios, four main types of taps are commonly used:

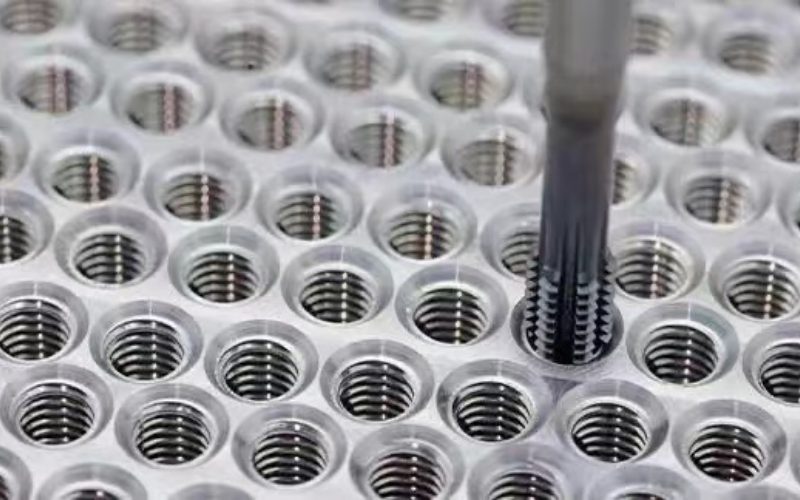

1.Spiral Taps: These have spiral grooves that effectively remove chips during cutting, reducing friction. They have

a long lifespan and are suitable for processing high-hardness metal materials. Spiral taps improve machining efficiency

and reduce tool wear, making them the most commonly used type of tap.

2.Forming Taps: These taps have no cutting edges and usually have one or more lubricant grooves. Their polygonal

shape forms threads by extruding the metal inside the hole. They are commonly used for processing small diameter

blind holes.

3.Straight Flute Taps: These are the simplest type of taps, but the torque and friction during cutting are relatively

high. Small diameter straight flute taps are prone to breaking and are less commonly used in CNC machining.

4.Point Taps: These taps have spiral-shaped chip removal grooves, making chip removal easy. They are particularly

suitable for blind hole threads and materials prone to forming chips, while maintaining good machining performance.

These four types of taps each have unique features and are commonly used in various part processing scenarios.

They are widely applied in the medical equipment, precision instruments, automotive, and mechanical processing

industries, effectively solving machining challenges.

Differences Between Hand Taps and Machine Taps

In actual machining, we often consider practical application scenarios and sometimes use different processing

methods and taps based on the workpiece's use. Generally, there are two types: hand taps and machine taps.

•Operation Method and Efficiency:

Hand Taps: Operators manually rotate the tap to cut internal threads, typically suitable for small batch production

or repair work. This method is flexible but relatively slow and depends on the operator's experience and skill.

Machine Taps: Mechanical equipment automatically controls the rotation and feed of the tap, suitable for large batch

production and precise machining needs. Machine taps improve production efficiency and consistency, reducing human

error and labor intensity.

•Accuracy and Repeatability:

Hand Taps: Dependent on the operator's skill level and manual rotation consistency, achieving high precision and

repeatability is challenging. Suitable for situations where high precision is not required or the number of workpieces

is small.

Machine Taps: Mechanical equipment's precise control ensures consistent thread quality and accuracy, ideal for

engineering projects requiring high precision threads and mass production.

•Application Range and Flexibility:

Hand Taps: Highly flexible, capable of handling various sizes and shapes of workpieces, especially advantageous for

non-standard or specially shaped workpieces.

Machine Taps: Suitable for large-scale production and standardized processes, highly efficient for producing a large

number of similar workpieces. However, handling non-standard shapes and sizes may require customized equipment

or fixtures.

When machining tapped holes, several important considerations must be taken into account to ensure the final machining

effect and part quality. These include but are not limited to:

•Thread Hole Cutting and Forming Methods: Internal threads can be made in holes through cutting or forming methods.

The specific choice depends on the hole size, material hardness, and whether the hole is blind or through.

•Using Standard Thread Sizes: Whenever possible, use standard thread sizes to simplify the machining process and ensure

the part's quality and accuracy. Common standard sizes include imperial and metric threads.

•Considering Inclined Surfaces: Machining inclined surfaces may increase the difficulty. It's necessary to add a flat surface

for the tapped hole to ensure the hole depth meets the design requirements.

Answer: Tap breakage is usually related to mismatched material hardness or improper cutting conditions. Choosing a tap

suitable for the material hardness and controlling good cutting speed and feed rate can reduce breakage risk.

Answer: Ensure the use of suitable drilling tools for pre-drilling and select a tap matching the intended thread size. Proper

cooling and lubrication, along with controlled machining parameters, are also key.

Answer: Regularly check the sharpness and condition of the tap. Clean and store them in a rust-free environment after

use to prevent moisture-induced rusting.

Answer: Ensure the blind hole depth is sufficient and use an appropriate tap type to ensure the internal thread is complete

and of good quality.